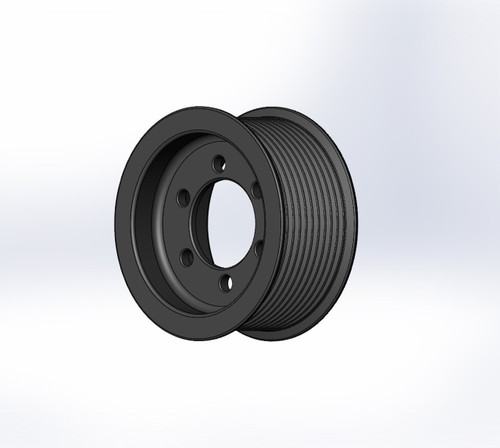

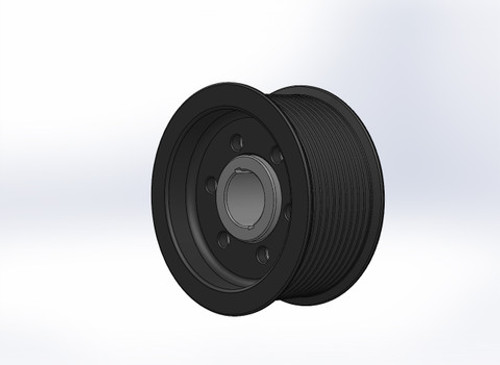

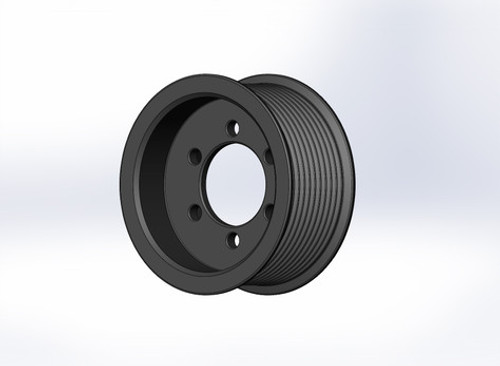

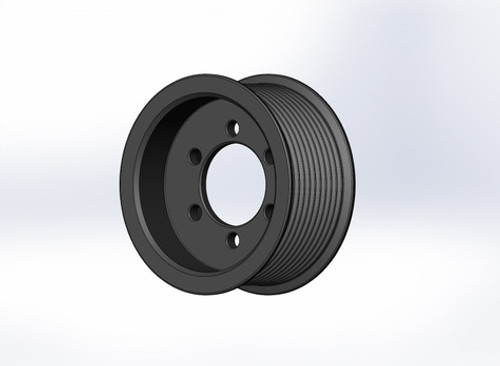

This is a Standard Spacing Style Procharger 10 Rib Pulley ONLY.

ZPE 2 Piece Griptec® pulley/system for ProCharger Superchargers.

This pulley is equipped with Griptec® a micro machining technology. This technology allows the maximum grip force to be applied to the pulley(s) and belt without adversely effecting your drive belt. Our Pulleys and Hubs are made from billet 7075 T6 Aluminum. This grade of Aluminum is much stronger and harder than billet 6061-T6. This gives us a strength similar to steel but with the light weight performance of Aluminum, further we hard anodize our parts for additional protection. This combination gives us the best that each material has to offer in strong light weight and tough component.

Our 2 piece system offers some additional features not found on other pulley systems. Our 2 Piece design allows for easy removal and installation in tight spaces. Space constraints are often found on reverse mount systems or small chassis setups. Not all kits have space limitations, there is another great feature our 2 piece systems offers up. That feature is adaptability for unique and custom offsets. Special offsets are often found in supercharger unit upgrades or custom race brackets. We bring the entire line up of Griptec® 2 piece pulleys to be adapted to a easily movable offset in a low cost solution, supporting super-fast production times to help get your supercharge setup aligned and ready for your boost goals. The ZPE 2 piece design will also reduce or even eliminate having to repeatedly deal with key-ways every time when swapping pulleys. When our hub/receiver is mounted it does not need to be removed for pulley swaps. Pulley swaps are easy with 6 easy to change M6 screws.

Always use Blue Loctite and use proper install tools to correctly TQ to 6-7 ft-lbs.

Pro Install Tips:

- Before installing you new pulley you may want to verify your pulleys alignment referencing your original pulley with the new Gritpec® Pulley.

If you wish to know more about how to do this chose from the Links. Pulley_vs_Pulley_Check.pdf Or Pulley_Vs_Pulley_Check_Video

- For the Stainless socket cap screws use a 5mm allen wrench. Tq M6 Screws to 6-7 Ft-Lb

- Do not use impacts for torqueing the pulleys hardware. We recommend a proper calibrated tq wrench. Over torqueing can lead to hardware failure.

- When swapping multiple pulleys/rings for different setups, inspect the dried Loctite and remove excess cured Loctite before re applying new Loctite. This will ensure that the new Loctite cures and bonds to the screws and hub/receiver. Using a right angle pick, light wire brush or pipe cleaner helps removed buildup of old Loctite.

- Follow your superchargers recommended TQ spec for the retention bolt or nut. We recommend using Loctite Blue or Red depending on your requirements.

- Don’t use an impact on the main shaft bolt/nut for the Hub/Receiver over torqueing can cause deformation of the hub or damage your shaft.

Other useful info.

You can reuse your keyways. For ProCharger systems the Keys are usually 3/16 key stock. Some factory pulleys may have only one Key. Our new Receiver is prepped with 2 keys for versions that use 2 keys. This extra Key slot will not affect anything if not being used.

Always use Blue Loctite and use proper install tools to correctly TQ to 6-7 ft-lbs.

Our Stainless hardware for our M6 thread is a M6x1.0 by14mm length.

Our ProCharger pulleys come standard with our Level 3 Griptec®.